Conveyor Belts – Guidelines for Storage and Handling

1. Scope

The standard gives full instruction on the appropriate conditions for belt storage and handling. It is not applicable for light conveyor belts required by EU standard EN873.

2. Packages

2.1 Reel

The finished belts should be packed into reels. The center core should withstand the weight of the reel weight without breaking. The core should have square or circular holes to make the steel spools available.

2.2 Bundle

2.2.1 Use the fabric, steel, or plastic straps to bundle the reels.

2.2.2 The straps should have enough tensile strength and can prevent the reels from opening in storage. The width of the straps should be big enough to prevent damage to the belt.

2.3 Protective layer

The outer package of the reel should be paper, sacking plastic, fabric, or other protective layers. If it is the under-ground fire-resistant belt, the packages should get rid of when moving the belt underground.

3. Storage

3.1 Environment

3.1.1 Normal Requirements

It is better to store the belt indoors. The recommended rubber storage condition should comply with ISO2230 standards.

3.1.2 Temperature

The belt should not be stored under very high or low temperatures.

The belt should be far from the heat sources (boiler, heat rejection radiator).

3.1.3 Humidity

The conveyor belt should be kept dry, there should be no water inner package. This is critical especially to the fabric belt.

3.1.4 Light

The conveyor belts should be kept from light (especially direct sunlight or UV radiation).

3.1.5 Ozone

The ozone has a big effect on some rubber products. Therefore, the warehouse that stores the belts should not contain any equipment with ozone (fluorescent lamp, mercury vapor light, HV equipment, and equipment that may cause sparks or electricity).

The warehouse should not contain any flammable air or steam, as it may cause ozone under light reaction.

3.1.6 Other hazardous materials

The belts should be protected from other hazardous materials (abrasive solutions such as acid, oil, and so on).

3.2 Storage Method

3.2.1 The axis should be in the horizontal direction when storing.

3.2.2 If the belt is stored outdoors, it should be put above ground to protect it from cement and sand. The shelf should be made of wood and the width of the batten should be big enough to protect the surface from big pressure.

3.2.3 If the conveyor belt is stored indoors, it can be put onto cement ground and use the cleat to make the goods stable.

3.2.4 Leave the hallway between reels both for indoor and outdoor storage.

3.2.5 For the reels with a mass over 10 MG (104 KG) or reels with a big cover thickness, insert the steel axis in the reels and use the frame to stand.

4. Lifting

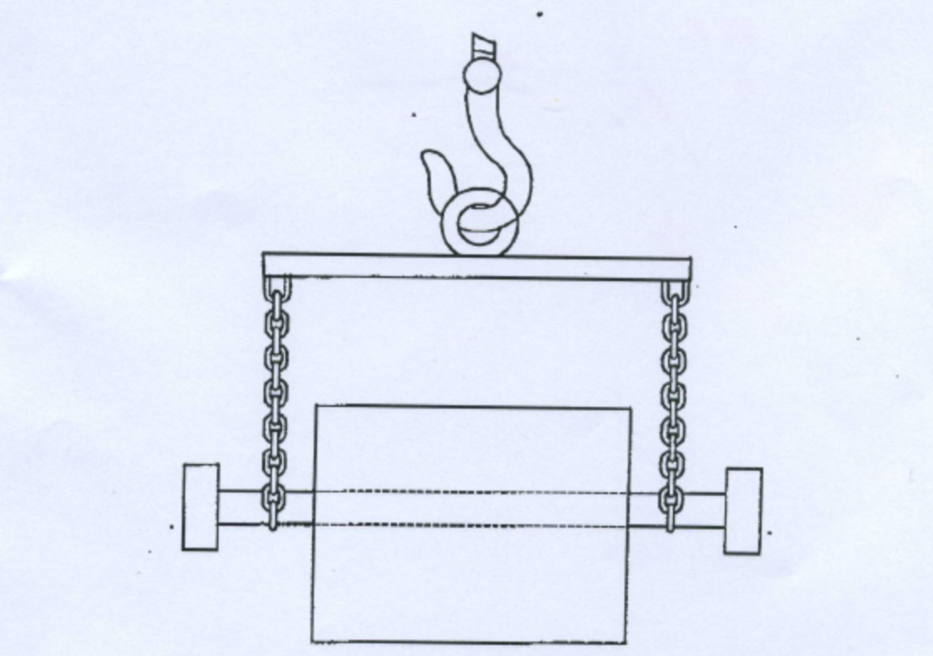

The recommended way of lifting is as follows: insert the steel stick with the right diameter into the center hole, contact the steel cord stay at the two sides of the lifting equipment hanging the stick with the two sides of the steel stick. The distance between the steel cords of hanging sticks needs wider than the belt width to avoid abrasion of the steel cords. (See drawing 1.)

Drawing 1- hanging stick or steel cord lifting

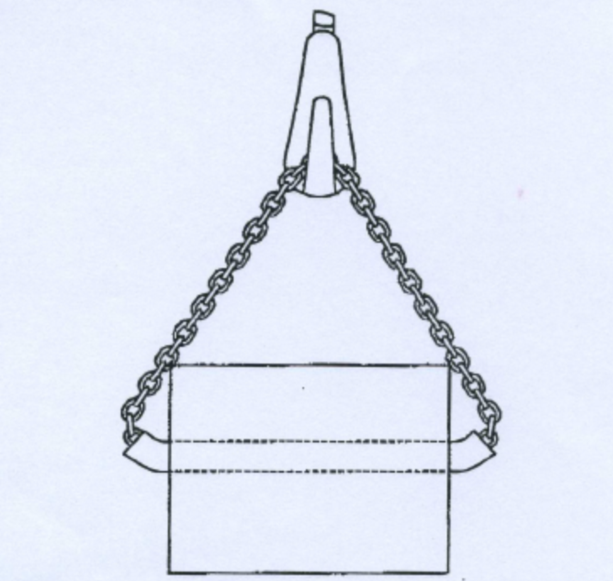

It is acceptable to lift directly by the cordage (instead of hanging a stick or steel cord) which across from the center hole if the cordage is right. (See drawing 2.)

Drawing 2-cordage lifting

Regarding the belt roll without break, we need two sticks inserted into the center holes in two rolls, the cordage needs to be longer enough to get together.

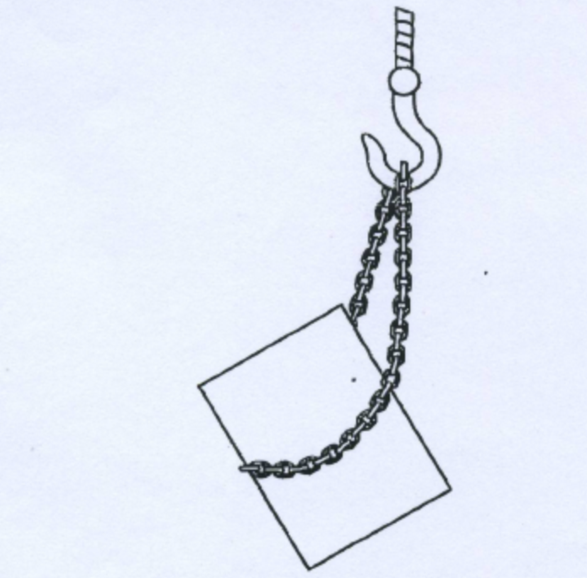

It is not acceptable to hold the outside or the hanging material of the belt roll to lift. Do not use the steel cord to lift directly without the hanging stick or reasonable frame to avoid the steel cord contacting the belt edge directly. Do not lift with the steel cord binding to the outside of the belt roll at any time, otherwise, the loading will be not balanced or the situation of the belt roll will be trapeziform. The belt will slide and possibly hurt the person. (See drawing 3.)

Drawing 3-unacceptable lifting

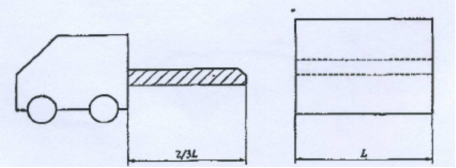

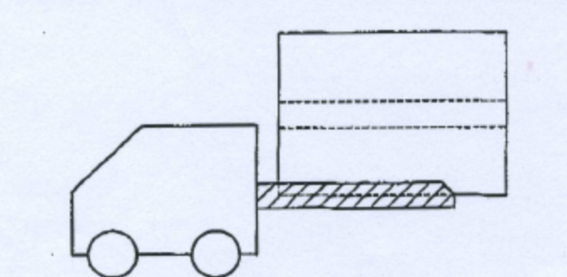

5. delivery for short distance by forklift

It is acceptable to deliver by reasonable forklift to delivery the belt for a short distance but needs to avoid damage to the outside of the belt. (See drawing 4.)

Drawing 4-delivery by forklift

It is also acceptable to deliver the belt by an adjustable single forklift, which need to be inserted into the center hole to lift up.

Need to understand national or safety regulations before using the forklift.

6. The assembly conveyor belt

6.1 Assembly on the old conveyor

Insert the steel stick into the center hole and assemble the belt roll and steel axle in the front of the conveyor. Notice that the top cover needs to face the front. Steel axle can run free on the A-frame and can stop it when necessary. Contact the old belt and new belt by temporary splice kit to lead the new belt into the system.

6.2 Assembly on the new conveyor

Fix the steel cord on the top or bottom of the belt by steel plate, to avoid the belt loop, the reasonable way is to support the two sides of the belt.