Abstract

This paper analyzes the common fault causes of the tubular belt conveyor and proposes methods for their prevention.

Keywords: tubular belt conveyer, off-tracking, tear, torsion, prevention

1. Introduction

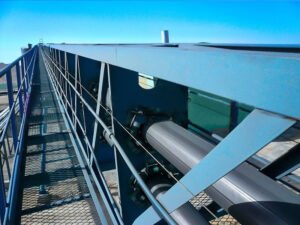

Tubular belt conveyors are a new type of bulk material transportation equipment, widely used in power, building materials, chemical, mining, metallurgical, port, and other industries. Faults in these conveyors can significantly impact production and cause substantial economic losses. Thus, preventing malfunctions and ensuring the safe, reliable, and efficient operation of tubular belt conveyors is crucial.

2. Common Faults and Their Causes

2.1 Off-Tracking of Conveyor Belt Ends

The most common malfunction in tubular belt conveyors is the belt ends running off-track. This can affect the conveyor’s lifespan and, in severe cases, lead to shutdowns. Causes of this fault include:

- Imperfections in the drum’s cylindrical accuracy.

- Unflexible roller rotations.

- Significant errors in the parallelism of the driving and driven drum axles.

2.2 Conveyor Belt Tear

Conveyor belts are designed to form a tube shape with fewer layers of fabric, making them more susceptible to tearing. Tears can be caused by:

- Severe wear and tear on the chute, allowing materials to strike the belt directly.

- Belt misalignment leads to scraping and tearing.

- Weak belt joints or excessive load causing joint failure.

2.3 Belt Twisting Leading to Belt Flipping

Belt twisting during operation is a frequent issue, with causes including:

- New belts create more resistance.

- Deformation or wear in mechanical parts over time.

- Insufficient precision in the manufacturing or installation of polygonal roller groups and support structures.

3. Prevention and Handling of Common Faults

3.1 Preventing and Managing Belt End Off-Tracking

Measures to prevent off-tracking include:

- Ensuring installation accuracy.

- Strengthen routine maintenance to clear debris from rollers and prevent belt misalignment.

- Install belt misalignment monitoring devices.

3.2 Preventing Belt Tears

To prevent tears:

- Promptly repair any worn parts of the chute.

- Address misalignment issues promptly to prevent further damage.

3.3 Preventing and Managing Belt Twisting

To prevent and manage belt twisting:

- Install run-off switches symmetrically on the unload rollers and reversing drum to ensure the conveyor operates within control.

- Ensure the belt is installed correctly to avoid twisting.

Conclusion

Given the high incidence of malfunctions and accidents with tubular belt conveyors, understanding the causes and timely addressing faults is essential for the safe operation of these conveyors. This analysis helps deepen the understanding of the equipment’s characteristics and conditions, laying a foundation for enhancing performance, extending lifespan, and reducing malfunctions.