Conveyor belts are crucial in conveyor systems and serve industries such as coal, mining, metallurgy, chemicals, construction, and transportation. They enable large-scale, continuous transportation of materials like granular, powdery, paste, and bulk items. This article covers the classifications, applications, and structures of conveyor belts to assist in selecting the right belt for specific operational needs.

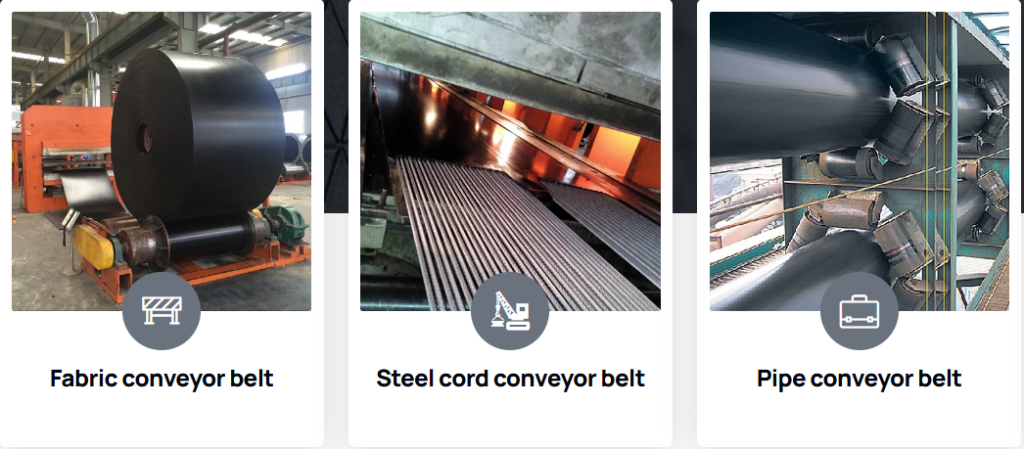

1. Types of Conveyor Belts and Their Applications

Conveyor belts are categorized based on their construction and specific operational requirements. The table below provides a summary of the primary types, along with their characteristics and appropriate usage:

These categories highlight the functional aspects of conveyor belts, with multi-functional types such as cold-resistant, flame-resistant, and anti-static belts becoming increasingly popular.

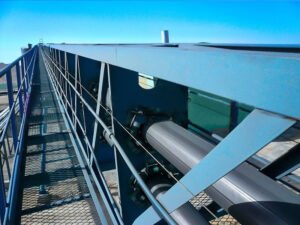

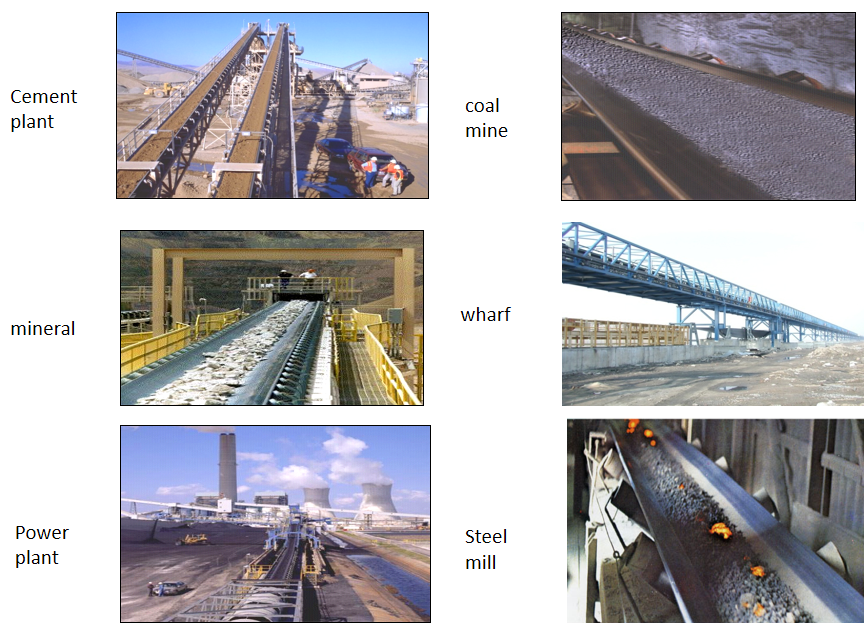

2. Conveyor Belt Applications by Industry

Conveyor belts play an integral role across multiple industries, including:

- Cement Plants: For transporting raw materials and finished products.

- Mining: Moving ores and rocks.

- Power Plants: Transporting fuel, including coal.

- Coal Mines: Continuous transport for coal extraction.

- Ports: Handling bulk goods.

- Steel Plants: Transporting raw materials and slag.

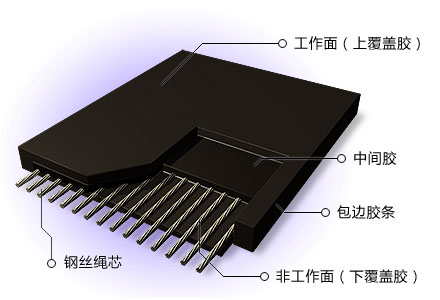

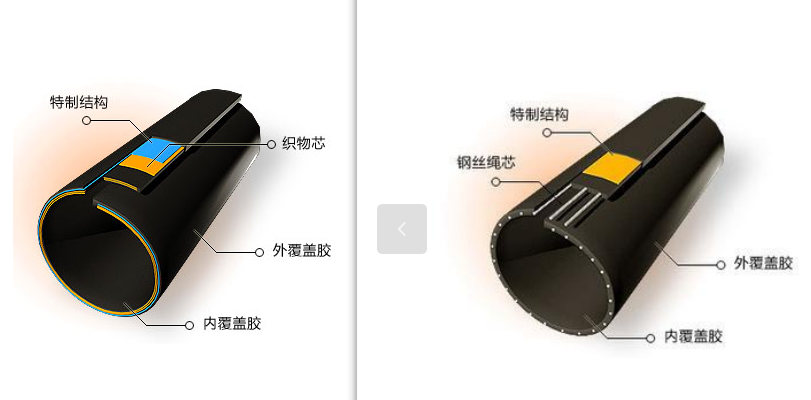

3. Structure of Steel Cord Conveyor Belts

Steel cord conveyor belts consist of:

- Cover Rubber: Provides tensile strength, durability, and abrasion resistance.

- Core Rubber: Enhances adhesion between steel cords, increasing durability.

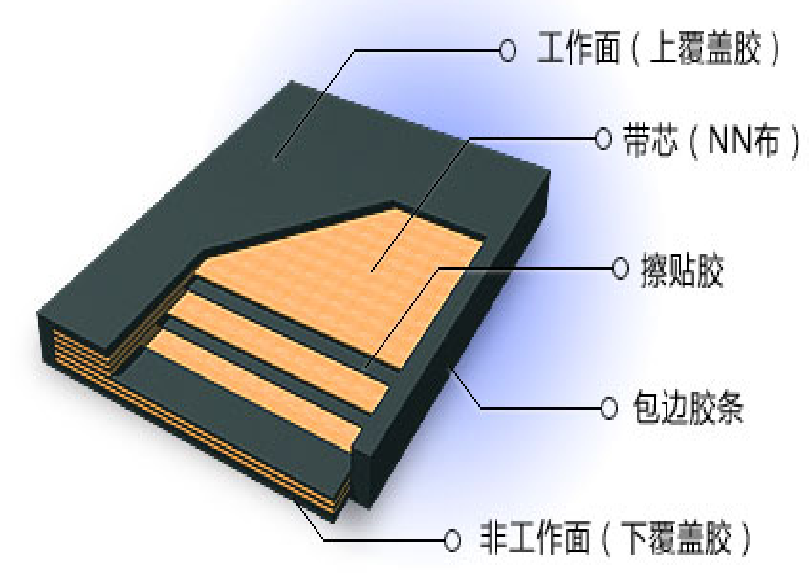

4. Structure of Layered Fabric Core Conveyor Belts

These belts have upper and lower cover rubber layers, which protect the belt core from direct impact, wear, and corrosion, thereby extending its lifespan. The top cover, also known as the working surface, faces the material, while the bottom cover contacts conveyor rollers. Side rubber strips are added to prevent edge wear.

5. Structure of Pipe Conveyor Belts

Pipe conveyor belts feature fabric or steel cord cores with a unique structure to meet both flexibility and rigidity requirements. This design allows them to form a tubular shape for closed transportation and flatten out for loading and unloading. Edge structures are designed to ensure effective sealing, preventing material leakage.

Understanding the various types, applications, and structural details of conveyor belts is crucial for selecting those that best meet specific industrial needs, thereby improving material handling efficiency and productivity.