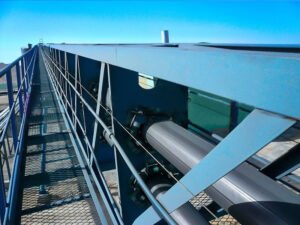

Conveyor Belt Standards

Exploring the Standards of Conveyor Belt Durability and Performance

In the world of material handling, the strength and durability of conveyor belts are paramount. We’ve delved into the conveyor belt standards to understand what sets apart the best in the business. From tensile strength to elongation at break, and abrasion to adhesion, these standards define the essential qualities that ensure reliability and efficiency in operations.

These insights into the different conveyor belt standards underline the importance of choosing the right conveyor belt grade for optimal performance and longevity. It’s not just about meeting the minimum requirements; it’s about exceeding them to ensure safety and efficiency in every operation.