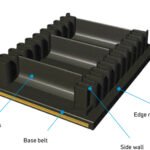

A sidewall conveyor belt is a type of conveyor belt that features vertical or angled sidewalls attached to the edges of the belt. These sidewalls serve to contain the conveyed material and prevent spillage, allowing for efficient transportation of bulk materials. Sidewall conveyor belts are commonly used in applications where there is a need to convey materials horizontally, vertically, or at angles. They are particularly useful in situations where space is limited or where materials need to be contained within the conveyor system to prevent spillage or loss.

Sidewall conveyor belt feature and classification

Sidewall conveyor belts have several distinctive features and can be classified based on various factors:

Features:

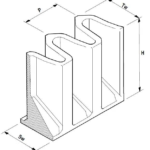

Vertical or Angled Sidewalls: The most prominent feature of a sidewall conveyor belt is the presence of vertical or angled sidewalls attached to the edges of the belt. These sidewalls help contain the conveyed material and prevent spillage during transportation.

Reinforced Construction: Sidewall conveyor belts are typically reinforced with textile or steel cords to provide strength and stability, especially when conveying heavy loads or operating in challenging environments.

Flexible Design: They offer flexibility in design, allowing for customization of sidewall height, spacing, and angle to suit specific application requirements.

High Tensile Strength: Sidewall conveyor belts are designed to withstand high tensile forces, ensuring reliable performance under demanding conditions.

Wide Range of Applications: These belts are suitable for a wide range of applications, including bulk material handling in industries such as mining, construction, agriculture, and waste management.

Classification:

Based on Sidewall Height: Sidewall conveyor belts can be classified according to the height of the sidewalls, which can vary depending on the specific requirements of the application. Common sidewall heights include low, medium, and high, with each offering different levels of containment and material retention.

According to Sidewall Angle: Sidewall conveyor belts can also be classified based on the angle of the sidewalls. The angle of the sidewalls determines the maximum incline or decline angle at which the belt can operate effectively. Common sidewall angles include 40°, 60°, and 90°, with steeper angles allowing for greater conveying inclines.

Material Construction: Sidewall conveyor belts can be classified based on the material construction, including the type of sidewall material (e.g., rubber, PVC, polyurethane) and the reinforcement material (e.g., textile, steel cords).

Application-Specific Classification: Sidewall conveyor belts may also be classified based on their specific application requirements, such as heavy-duty conveying, steep incline conveying, or corrugated sidewall design for improved material retention.

Overall, sidewall conveyor belts offer versatile and efficient solutions for conveying bulk materials while ensuring containment and preventing spillage in various industrial applications.

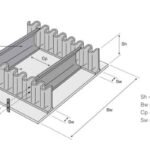

Sidewall belt technical datas

Our sidewall conveyor belts:

- Cleats height from 35mm to 460mm.

- Swall from 40mm-500mm.

- Width from 300mm-1800mm